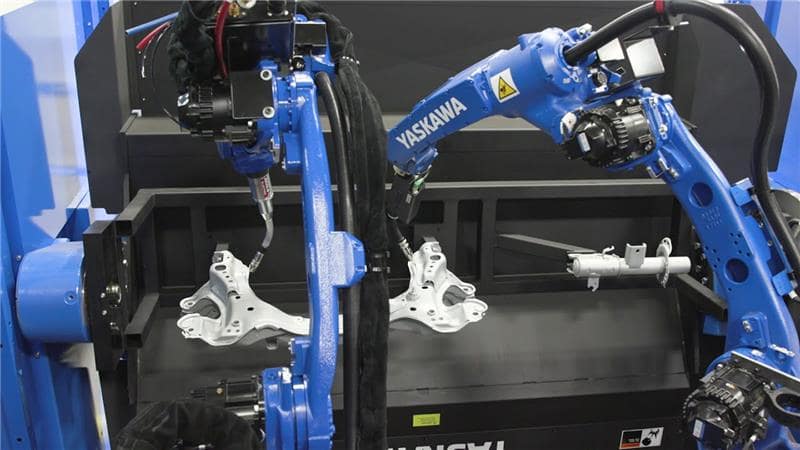

In a world where manufacturers must meet rising production demands while ensuring quality and worker safety, arc welding automation is no longer optional—it’s essential. The Yaskawa Motoman AR1440 welding robot is a standout solution for high-speed, precision welding tasks. Trusted across industries like automotive, agriculture, heavy equipment, and metal fabrication, the AR1440 strikes a powerful balance between performance, flexibility, and affordability.

Designed to excel in MIG and TIG welding, this 6-axis industrial robot offers superior path accuracy, compact form, and easy integration with major welding systems—making it a top choice for robotic welding cells.

Technical Specs: What the AR1440 Brings to the Table

| Specification | Detail |

| Payload Capacity | 12 kg |

| Horizontal Reach | 1,440 mm |

| Repeatability | ±0.02 mm |

| Axes | 6 |

| Mounting Options | Floor, wall, ceiling, tilt |

| Controller | YRC1000 |

| Weight | Approx. 130 kg |

Key Functional Capabilities

- Fast Arm Speeds: Increases weld throughput by reducing arc-off time

- Compact Profile: Slim arm easily accesses tight spaces and fixtures

- Internal Cable Routing: Weld cables run through the arm for fewer tangles and longer cable life

- Torch Compatibility: Supports torches from Fronius, Lincoln Electric, Miller, OTC, and others

- Arc Start Stability: Maintains consistent weld penetration and reduces spatter

- Seam Tracking Ready: Compatible with real-time laser or tactile seam trackers

Real-World Applications: Welding in Action

The AR1440 has been successfully deployed in a wide variety of environments, from OEM automotive production lines to high-mix job shops. Below are examples of industries where the AR1440 is actively replacing manual welding:

| Industry | Common Task | Integration Region |

| Automotive | Spot and seam welding of chassis frames | USA, Mexico, Germany |

| Agricultural Equipment | MIG welding tractor frames | Brazil, India |

| Metal Furniture | Frame and panel welding | Southeast Asia |

| Trailer Manufacturing | Long seam welding with tracking | North America |

| Heavy Equipment | Reinforced steel parts | UAE, South Korea |

YRC1000 Controller: Powerful Yet Simple

Every AR1440 is controlled by Yaskawa’s YRC1000 controller, which is compact, fast, and versatile. It includes:

- Ethernet/IP, Profinet, and DeviceNet support for factory-wide communication

- MotoSim offline programming for planning, testing, and simulating weld paths

- Smart Pendant compatibility for drag-and-drop programming

- Seam tracking, weave, and torch angle adjustment tools built-in

- Safety I/O with optional FSU (Functional Safety Unit)

This makes it easy to integrate into new or legacy production lines with minimal downtime.

Benefits at a Glance

| Feature | Benefit |

| Speed & Accuracy | Maintains ±0.02 mm repeatability at high speeds |

| Durability | Designed for 24/7 operation in harsh welding environments |

| Flexibility | Supports floor, wall, or inverted mounting for space savings |

| Cleaner Work | Reduces spatter and rework with consistent weld quality |

| Cost-Efficient | Affordable upfront with rapid payback in labor and defect reduction |

Considerations Before You Deploy

While the AR1440 is incredibly efficient, it’s not without its limitations:

- 12 kg payload limit means it’s best suited for light- to mid-weight torch systems

- Requires safety zoning or fencing (not collaborative/cobot)

- Not ideal for very large parts that exceed its 1.44 m reach

- Offline programming recommended to maximize uptime and accuracy during deployment

The Future of Robotic Welding with Yaskawa

Yaskawa continues to push the boundaries of robotic arc welding by introducing:

- AI-enhanced seam following and torch correction

- Real-time adaptive welding based on camera feedback

- Cloud diagnostics and predictive maintenance via smart controllers

- Collaborative-capable safety zones to reduce floor space needs

With an expanding lineup of welding-specific robots and software upgrades, Yaskawa is firmly positioning itself at the center of Industry 4.0-ready welding automation.

Is the AR1440 Right for You?

Choose the AR1440 if your operation involves:

- High-volume MIG or TIG welding

- Tight fixtures or compact work envelopes

- Need for repeatability, accuracy, and minimal arc downtime

- A goal to reduce reliance on hard-to-find skilled welders

This robot is especially well-suited to shops that want to scale efficiently without sacrificing quality.

Ready to Automate Your Welding Line?

At SmartHubShopper.com, we help you evaluate and compare robotic welding solutions like the AR1440—based on your production goals, part specs, facility layout, and integration needs.