Industrial robots are programmable, electromechanical systems used to automate tasks in manufacturing, assembly, welding, packaging, and material handling. These robots increase speed, precision, safety, and scalability—powering the global shift toward Industry 4.0 and fully connected smart factories.

Types range from robotic arms to collaborative cobots, with applications in nearly every industrial sector from automotive to electronics and aerospace.

Leaders on the Line: Top Robots Driving the Industry

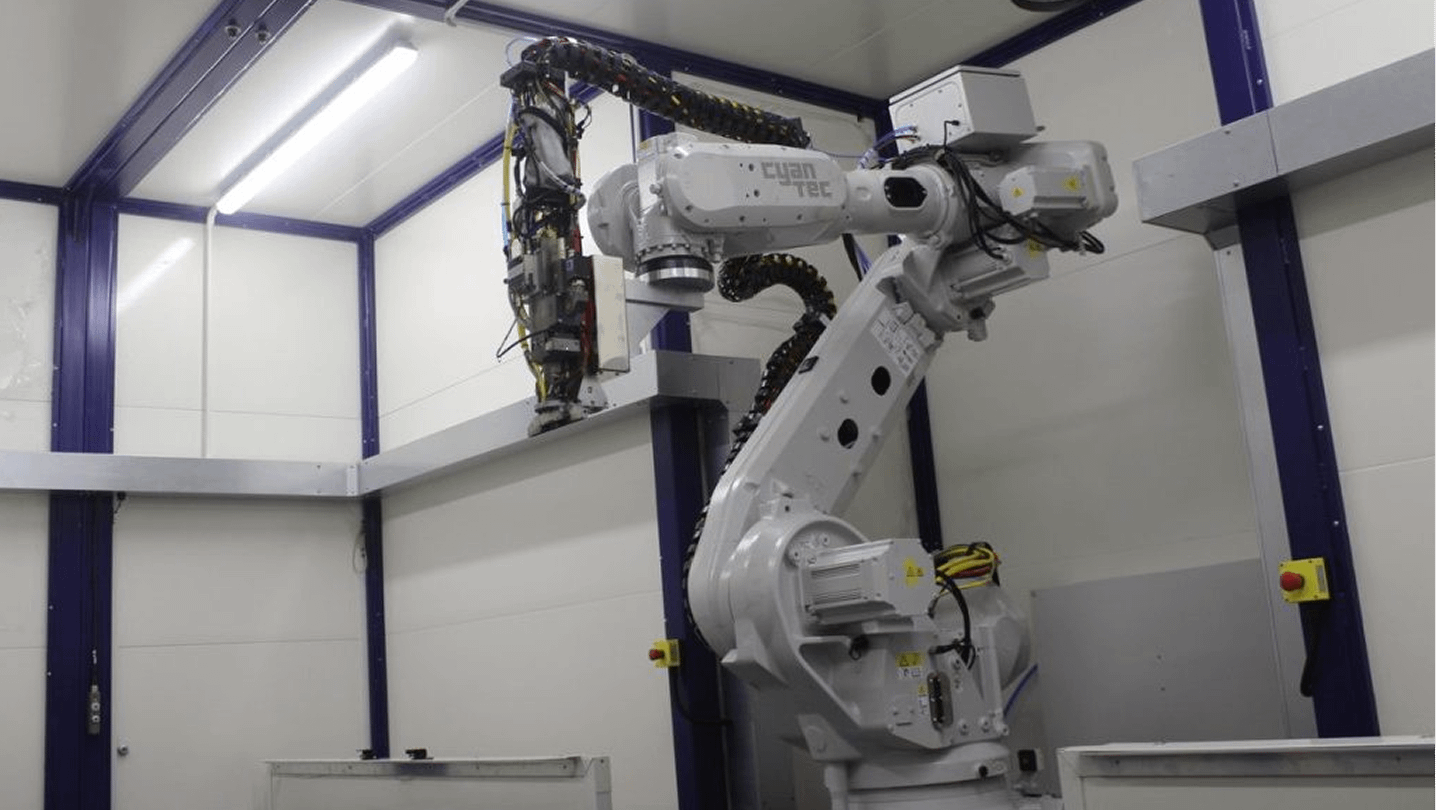

1.ABB IRB 6700 – Built for Heavy Lifting

- Manufacturer: ABB Robotics

- Best For: Automotive, metal fabrication, material handling

- Core Features:

- Payload: Up to 300 kg

- Range: 2.7 meters

- High-speed welding, grinding, and palletizing

- Use Case Highlight:Volvo’s Gothenburg plant uses the IRB 6700 for 24/7 precision welding with 99.9% uptime.

- Price Estimate: ~$60,000–$100,000

- Explore IRB 6700

2.FANUC M-20iA – The High-Speed Workhorse

- Manufacturer: FANUC America

- Best For: High-speed assembly, packaging, and machine tending

- Core Features:

- Payload: 20 kg

- Repeatability: ±0.03 mm

- Slim arm design fits in tight spaces

- Use Case Highlight:In electronics manufacturing, M-20iA units are used to assemble smartphone components with sub-millimeter accuracy.

- Price Estimate: ~$30,000–$50,000

- Meet M-20iA

3.UR10e – The Flexible Cobot

- Manufacturer: Universal Robots

- Best For: Collaborative tasks, small-scale manufacturing

- Core Features:

- Payload: 12.5 kg

- Safety-compliant for working alongside humans

- Easy programming via touchscreen interface

- Use Case Highlight:In a Danish furniture plant, UR10e cobots assist human workers in gluing, screwing, and quality testing chairs—cutting defect rates by 40%.

- Price Estimate: ~$45,000

- View UR10e Specs

Automation in Action: Real-World Deployments

| Industry | Robot Used | Application | Impact |

| Automotive (Germany) | ABB IRB 6700 | Weld shop robot cell | Increased speed & reduced injuries |

| Consumer Electronics | FANUC M-20iA | Circuit board placement | Higher throughput, 24/7 operation |

| Furniture (Denmark) | UR10e | Collaborative assembly | 40% fewer product defects |

Smarts vs. Spend: Is It Worth It?

| Advantage | Limitation |

| Precision, consistency, safety | High initial investment |

| Low downtime, 24/7 productivity | Requires operator training or integrators |

| Reduces repetitive strain | Limited flexibility on mixed-product lines |

What’s Coming to the Factory Floor

The next wave of industrial robots includes:

- AI-driven defect detection

- Mobile robotic arms for dynamic workflows

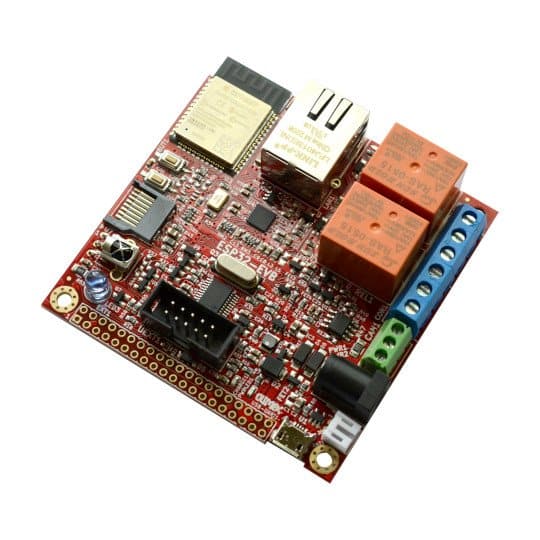

- 5G-enabled real-time control

- Cloud-managed robot fleets

Startups like Ready Robotics and Rever are simplifying integration with drag-and-drop programming for SMEs, while big players like Siemens are combining robotics with industrial IoT platforms for predictive maintenance and digital twins.

Find Your Factory’s Perfect Robot

Whether you’re scaling up production or starting your smart factory journey, SmartHubShopper.com provides curated industrial robot recommendations based on task type, budget, and production scale.