Is This a Cobot, or Just a Robot?

Misconceptions and Corrections in the Collaborative Robotics Market

When you walk into a factory today, you might see an industrial robot with a shiny safety scanner attached to it, moving slower when people get close. Many integrators — and even sales teams — will call this setup a cobot. But is it really?

The answer: not necessarily.

🤖 Robot vs. Cobot: What’s the Difference?

- A robot is any programmable machine that can move and perform tasks.

- A collaborative robot (cobot) is specifically designed to work safely alongside humans.

To earn that label, a cobot must comply with ISO 10218 and ISO/TS 15066 safety standards, supporting collaborative modes such as:

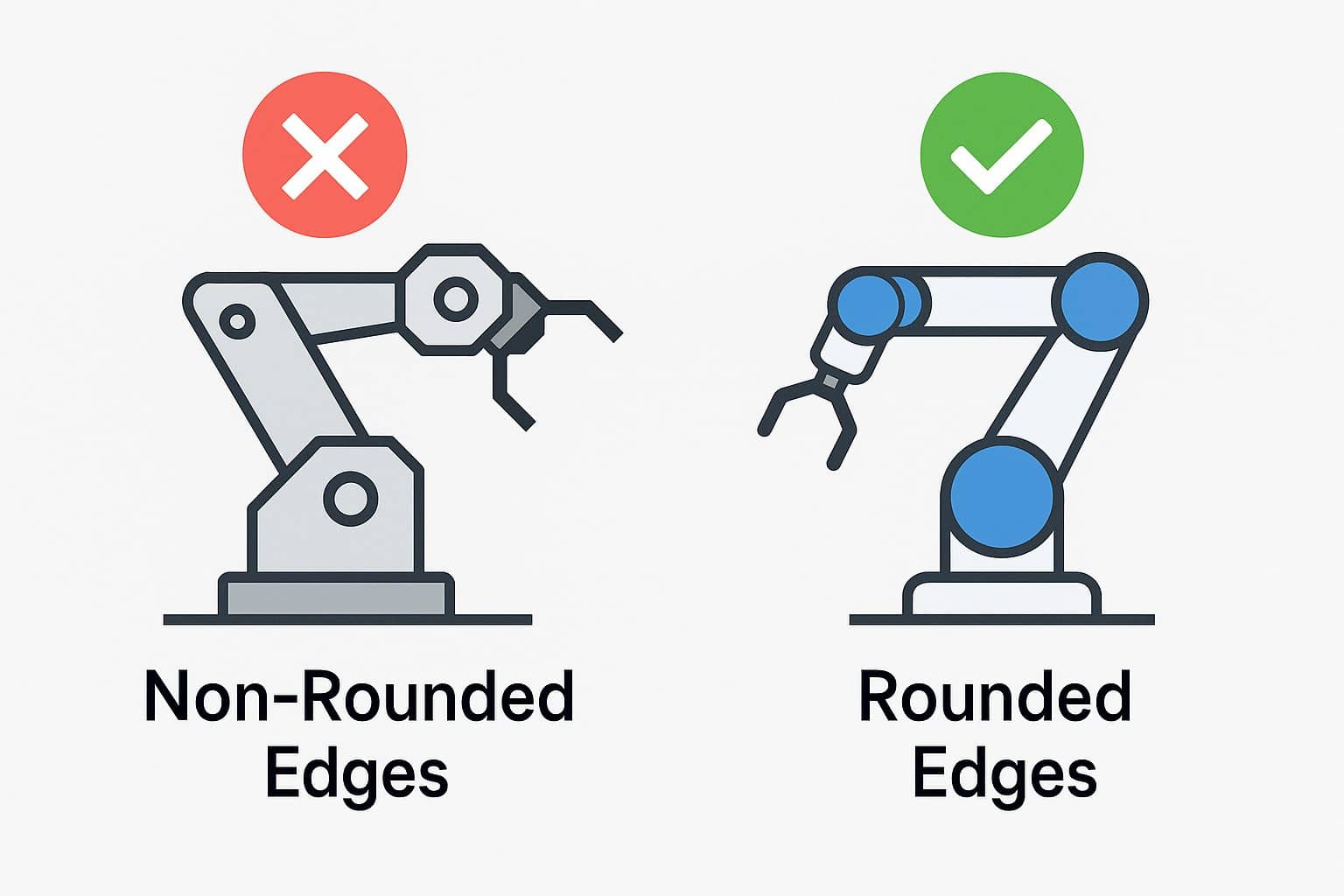

- Power & Force Limiting (PFL): Rounded edges, torque sensors, and lightweight designs prevent injury on contact.

- Speed & Separation Monitoring (SSM): The robot slows or stops when a person enters a safety zone.

- Hand Guiding: Safe, direct human control of the robot.

- Safety-rated Stop: Controlled halt when required.

❌ Common Misconceptions

“If I add a scanner, my robot becomes a cobot.”

Not true. A safety scanner enables SSM, but the robot’s design (sharp corners, high inertia) may still make close interaction unsafe.

“All slow-moving robots are cobots.”

Wrong again. Speed reduction helps, but without certified force/torque monitoring, the robot may still cause injury.

“Collaborative = small and weak.”

Some cobots lift over 30kg — but they are engineered with force-limiting joints and rounded casings. Size isn’t the deciding factor.

🔧 The Retrofit Market: Safety Packages for Robots

There are solutions that make a standard robot more collaborative, but they don’t change the robot’s DNA. Instead, they add safety functions so humans and robots can share a workspace.

| Vendor / System | What It Adds | Certification | Use Cases |

|---|---|---|---|

| Veo Robotics – FreeMove (now Symbotic) | 3D vision for speed & separation monitoring | ISO 13849 PLd Cat 3 | Automotive, heavy payload robots |

| SICK – SRAP | Safety laser scanners + robot control integration | ISO 10218 | Machine tending, logistics |

| B&R – SafeROBOTICS | Software modules for hand guiding, safe speed | PL e, SIL 3 | Retrofit on ABB/KUKA/FANUC arms |

| KUKA / FANUC DCS | Native safety software | TÜV-certified | Built-in OEM options |

These kits enforce safety-rated stops and separation, but they do not give the robot power & force limiting (PFL) by default. That means the robot can slow down and stop safely, but it may not be safe to directly guide or share physical contact.

✅ So, When Is It Truly a Cobot?

- When it meets ISO/TS 15066 collaborative operation requirements.

- When it is designed from the ground up for safe contact (rounded edges, torque sensing, force limiting).

- When it passes safety validation by a certified integrator.

Adding scanners and software can make a robot “collaborative-capable,” but not all such robots should be marketed as cobots.

🎯 The Takeaway for Buyers

- Ask vendors if the robot is certified as a cobot under ISO/TS 15066.

- If it’s a retrofit package, clarify which collaborative modes are enabled (usually SSM + stop).

- Don’t assume slow = safe. Look for documented force, speed, and safety ratings.

At Mendy’s, our mission is to help buyers cut through the noise. Whether you need a true cobot, or a safe retrofit solution for an existing robot, knowing the difference could save money — and protect your workers.