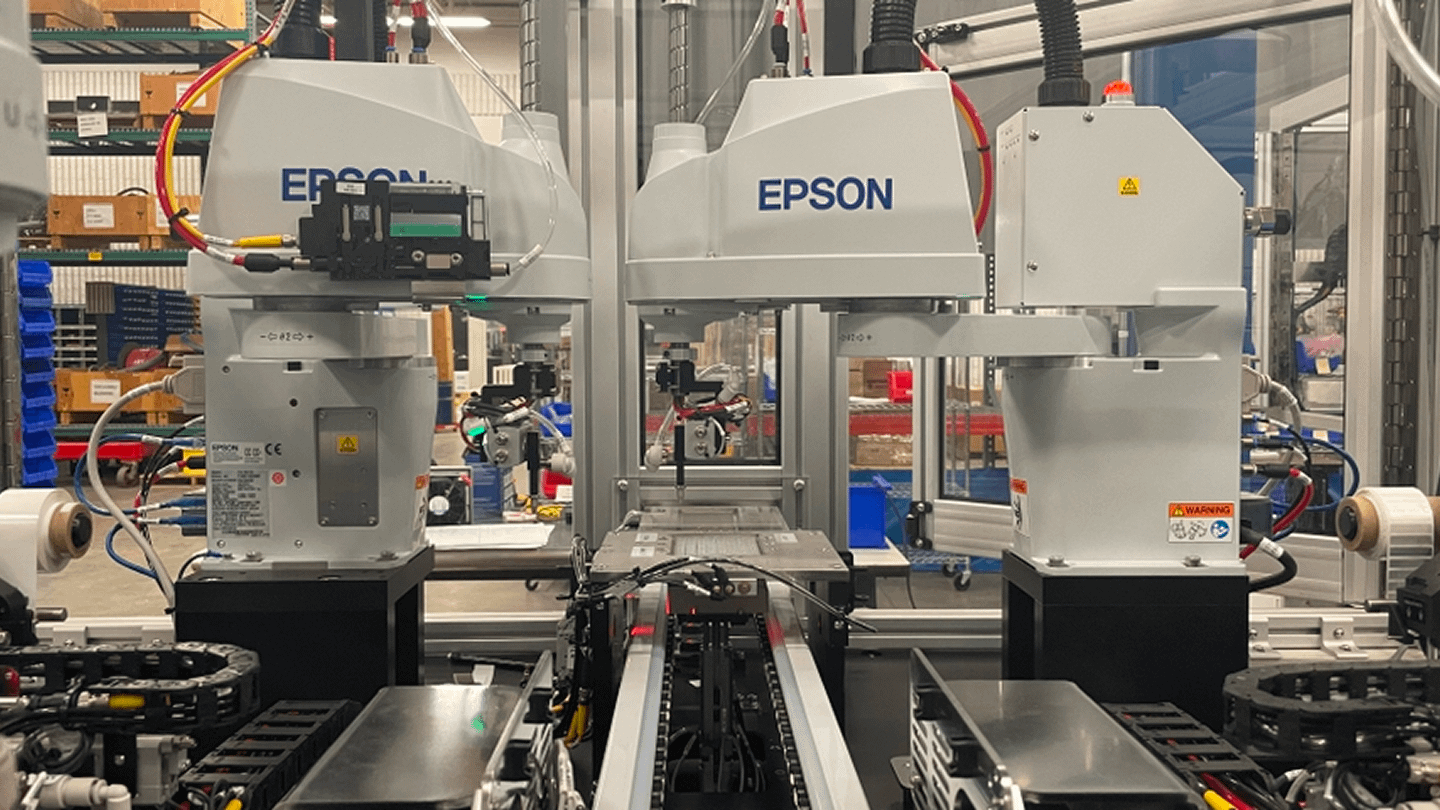

Epson may be best known for its printers and imaging systems, but within the world of factory automation, it’s recognized as a leader in industrial robotics, especially in sectors requiring micron-level precision, fast cycle times, and space-efficient design.

With over 40 years in robotics, Epson has deployed tens of thousands of robots worldwide—primarily in electronics, medical device production, automotive parts, and high-speed packaging lines. Its core strengths lie in SCARA (Selective Compliance Assembly Robot Arm) and 6-axis robotic solutions, backed by powerful controllers and integrated vision systems.

Whether you’re building smartphones or assembling syringes, Epson robots help manufacturers streamline repetitive processes with incredible reliability and speed.

Robot Families: What Epson Offers

1.SCARA Robots (G-Series, LS-Series, T-Series)

Epson’s SCARA robots are famous for their precision and compact footprint. These robots excel in high-speed pick-and-place tasks, circuit board assembly, and lab automation.

- Key Features:

- Speeds up to 0.37 seconds per cycle

- Repeatability of ±0.005 mm

- Payloads up to 20 kg (G-Series)

- Cleanroom and ESD models available

- T-Series models include built-in controller and power supply—ideal for low-cost integration

- Ideal Use Cases:

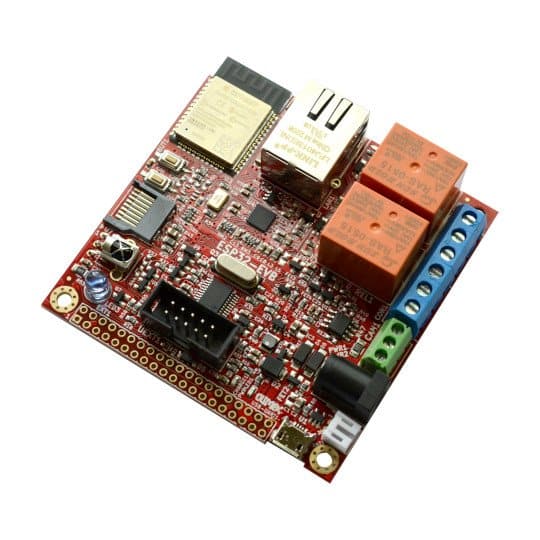

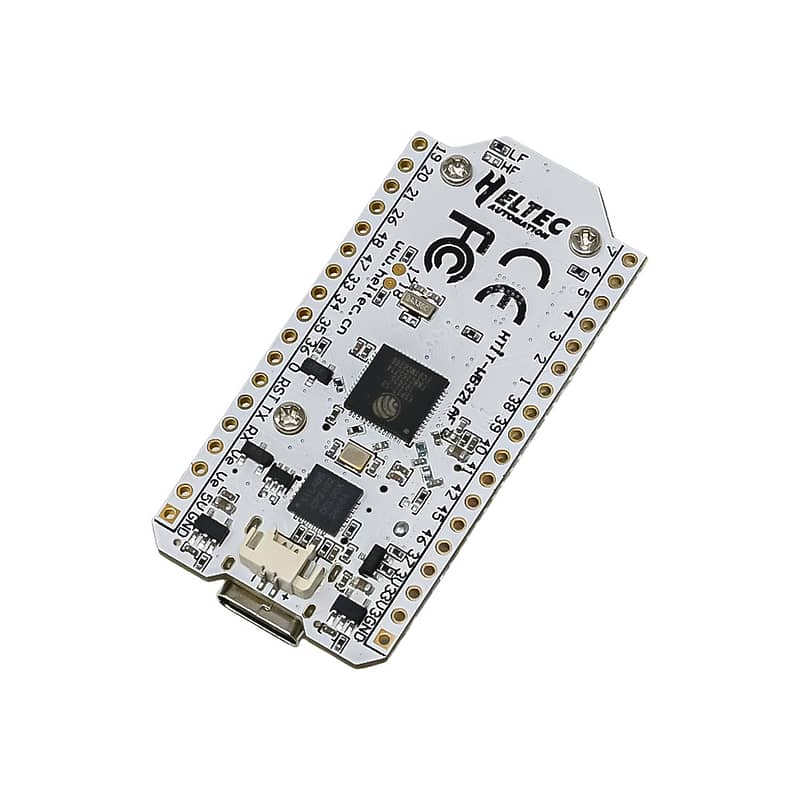

- Placing micro-components on PCBs

- Sorting and assembling medical parts

- Fast labeling and box packing lines

2.6-Axis Robots (C-Series, N-Series)

Epson’s 6-axis robots are designed for more complex tasks that require multiple degrees of motion, such as handling objects at awkward angles or inside tight enclosures.

- Key Features:

- Compact folding arm design (N-Series) reduces space by up to 40%

- Payloads up to 12 kg

- Floor, ceiling, and wall mount options

- Smooth motion profile for delicate part handling

- Common Applications:

- Assembling automotive relays and connectors

- Dispensing adhesives in tight assemblies

- Product testing and inspection

3.Vision and Force Sensing Integration

Epson’s optional Vision Guide system allows robots to identify parts, detect defects, and dynamically adjust positioning. It’s fully integrated into Epson RC+ software—no third-party systems required.

The company also offers force sensors for tasks requiring tactile feedback like pressing, inserting, or torqueing components.

Global Use Cases: Epson Robots in the Real World

Here’s how manufacturers are applying Epson’s robot lineup:

| Industry | Use Case | Robot Model | Region |

| Electronics | Precision placement of capacitors | G6 SCARA | Japan, Vietnam |

| Life Sciences | Syringe packaging & sorting | LS3 SCARA | Germany |

| Automotive | Relay assembly & inspection | C4 6-Axis | Mexico |

| Consumer Goods | Bottle labeling, cap sealing | T6 SCARA | USA |

| Medical Devices | PCB solder paste application | N2 6-Axis | South Korea |

Benefits of Using Epson Industrial Robots

- Space Optimization: Epson’s ultra-compact robot arms can be integrated into tight assembly lines with minimal modification.

- High-Speed Precision: Their robots are among the fastest in the SCARA category, ideal for reducing cycle times.

- Energy Efficiency: Low power consumption (T-Series SCARA can operate with a standard outlet).

- Ease of Use: Intuitive RC+ development software supports simple programming, simulation, and real-time monitoring.

- Scalability: From low-volume labs to full-scale factories, Epson’s modular systems grow with your business.

Limitations & Considerations

While Epson robots excel in precision assembly and lightweight material handling, they may not be ideal for:

- Heavy-duty industrial lifting (above 20 kg)

- Harsh environments like welding or foundry work

- Highly mobile applications (not designed as mobile robots)

Also, integration with third-party ERP or MES systems may require middleware if not using Epson’s proprietary APIs.

What’s Next for Epson Robotics?

Epson is investing in future-proofing its lineup with:

- AI integration for intelligent part recognition

- Edge computing controllers to reduce latency

- Enhanced collaborative safety features for robots working alongside humans

- Remote diagnostic capabilities for Industry 4.0 maintenance strategies

Final Thoughts: Is Epson Right for Your Factory?

If you’re looking for speed, accuracy, and easy deployment in assembly, inspection, or sorting tasks—Epson industrial robots offer a strong ROI with world-class precision. Whether you’re building circuit boards or packaging syringes, they deliver automation that scales with you.

Need Help Selecting an Epson Robot?

Let the experts at SmartHubShopper.com help you configure the perfect Epson solution based on your industry, production goals, and budget.