FFRobotics

Tel Mond, Israel

FFRobotics is a pioneering AgTech company revolutionizing the way fresh fruit is harvested. Founded in 2014 and headquartered in Tel Mond, Israel, the company develops fully automated robotic solutions that bring precision, efficiency, and scalability to modern orchards. Its flagship product, the FFRobot, is designed to mimic the dexterity of the human hand, enabling bruise-free harvesting of a wide range of tree fruits, including apples, citrus, pears, peaches, and mangoes.

The FFRobot utilizes advanced computer vision, machine learning algorithms, and a robotic operating system to identify, classify, and harvest fruit autonomously. Equipped with twelve independent robotic arms, the system can pick up to 9,000 fruits per hour, dramatically outperforming traditional manual labor while maintaining high standards of quality. The harvested fruit is carefully placed onto automated conveyor systems for safe collection, reducing handling damage and increasing operational efficiency.

Beyond harvesting, FFRobotics is expanding its technology to support orchard management tasks such as fruit thinning and pruning, offering a comprehensive solution for growers. By addressing labor shortages, lowering operational costs, and improving fruit quality, FFRobotics provides a sustainable, scalable, and technologically advanced approach to agriculture. The brand represents innovation, reliability, and a commitment to shaping the future of automated farming worldwide.

- AviKahani@FFRobotics.com

- +972-545-615-020

- 12 Gesher HaEts, Industrial Park Emek Hefer 3877701 HaMerkaz, Israel

Company Information

FFRobotics, founded in 2014 and headquartered in Tel Mond, Israel, is a leading AgTech company specializing in the development of fully automated fresh fruit harvesters. The company’s flagship product, the FFRobot, is a patented robotic platform designed to emulate the human hand’s dexterity and precision, enabling efficient, cost-effective, and bruise-free harvesting of various tree fruits, including apples, citrus, pears, peaches, and mangoes.

The FFRobot operates autonomously, utilizing advanced image processing, machine learning algorithms, and a robotic operating system to identify, classify, and harvest ripe fruit based on grower-defined criteria. Equipped with twelve independent robotic arms, the system can harvest up to 9,000 fruits per hour, significantly outperforming human pickers in both speed and consistency. The harvested fruit is gently placed onto an automated conveyor system, which transports it to bins for collection.

Beyond harvesting, FFRobotics is developing capabilities for fruit thinning and pruning, aiming to provide a comprehensive orchard management solution. The company’s technology addresses labor shortages, reduces operational costs, and enhances fruit quality, offering growers a sustainable and scalable solution for modern agriculture.

Products

Newsletter

Latest Products

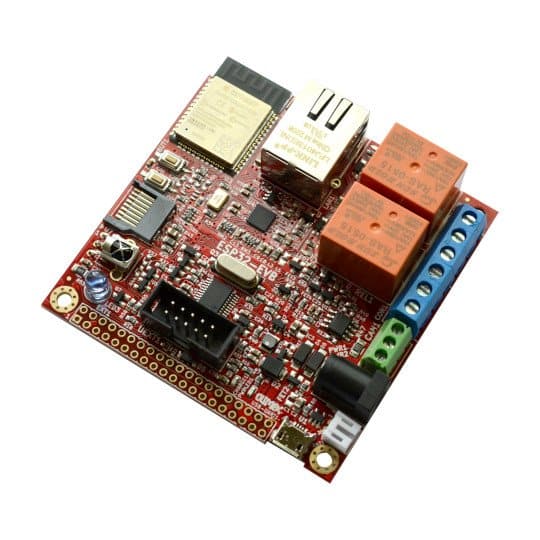

ESP32-EVB is an industrial-grade development board with Ethernet, relays, CAN bus, and microSD — perfect for robotic automation, gateways, or industrial IoT systems with rugged connectivity needs.

Olimex ESP32-EVB

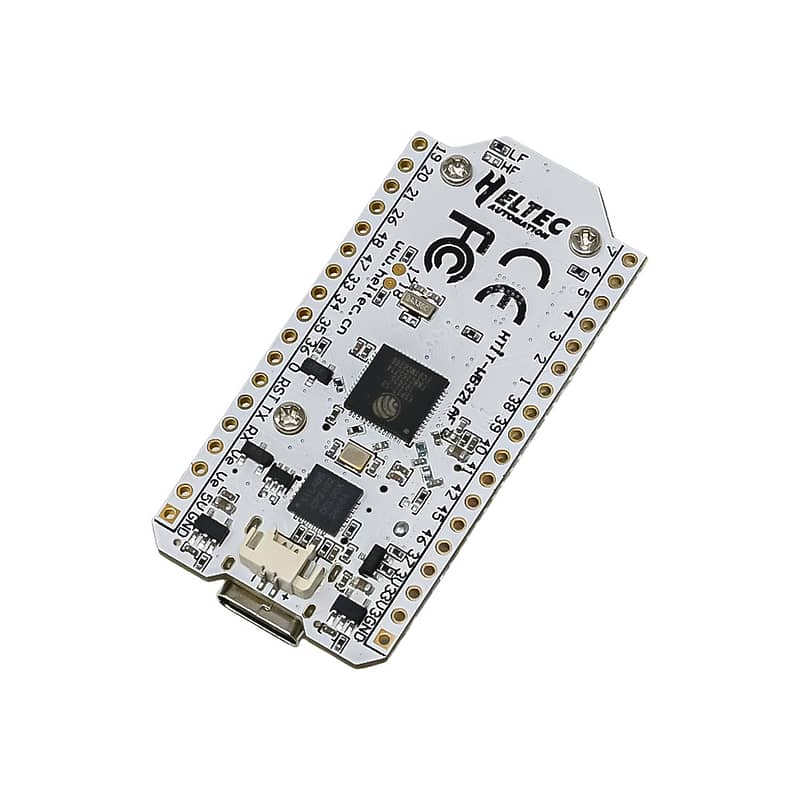

Combines ESP32 with LoRa transceiver and OLED screen. It’s designed for long-range telemetry and low-power robotics like delivery drones, field monitors, and agricultural bots.

Heltec WiFi LoRa 32 (V3)

Events

Shopper Insights Tech Showcase

Live demos of AI-driven shopper research tools, including biometrics, neuromarketing, and ethnography